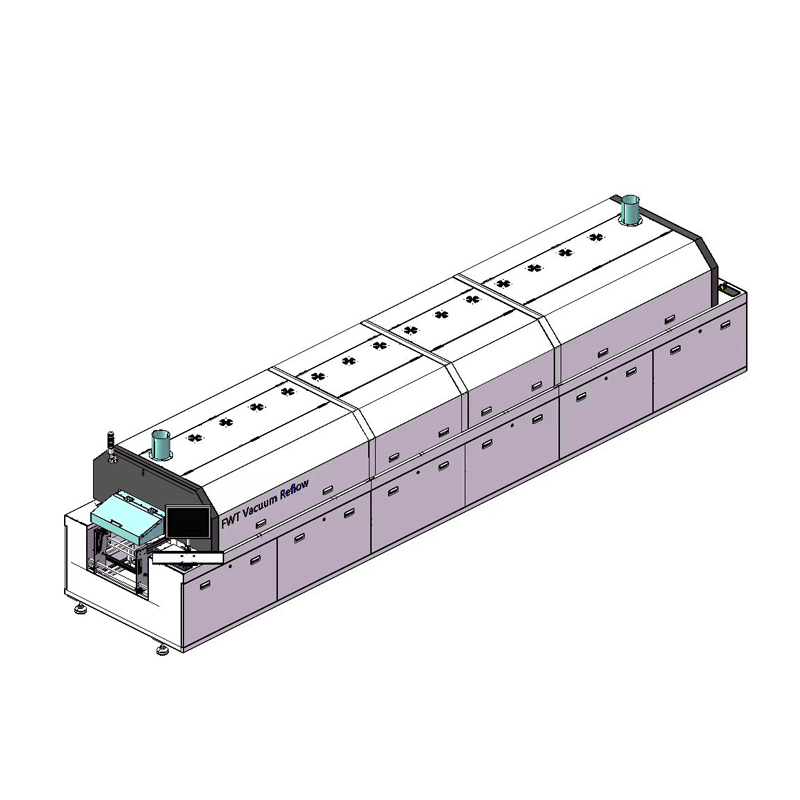

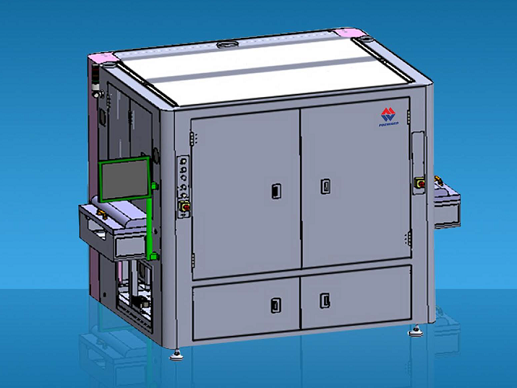

Bilateral plug-in 2-in-1 pannerCategory:SMT Peripheral Series

0512-65201865 / 133-8217-7188

Product Features

· Connection of single-rail equipment and dual-rail equipment in SMT production lines to realize two-in-two/two-in-one functionality

· U-shaped production line/two-in-one production line, changing the direction of PCB transfer by means of load shifting.

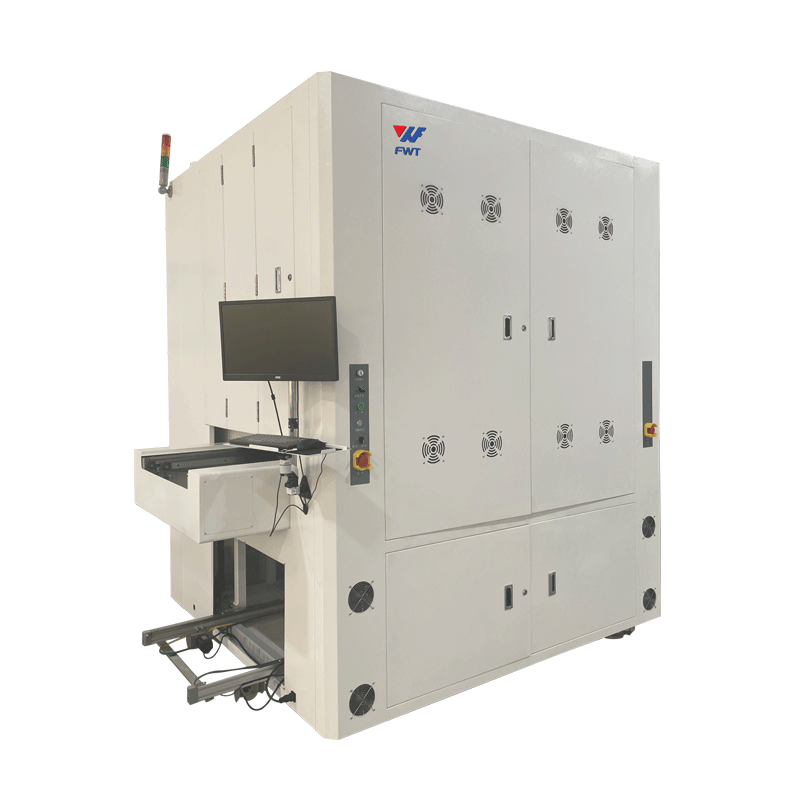

· Can be customized according to the actual needs of double track single head/single track double head/extended type transfer mechanism and Mitsubishi PLC control.

· PLC control system, touch screen operator interface, standard SMEMA signal port

· Servo motor shift structure / speed can be set arbitrarily

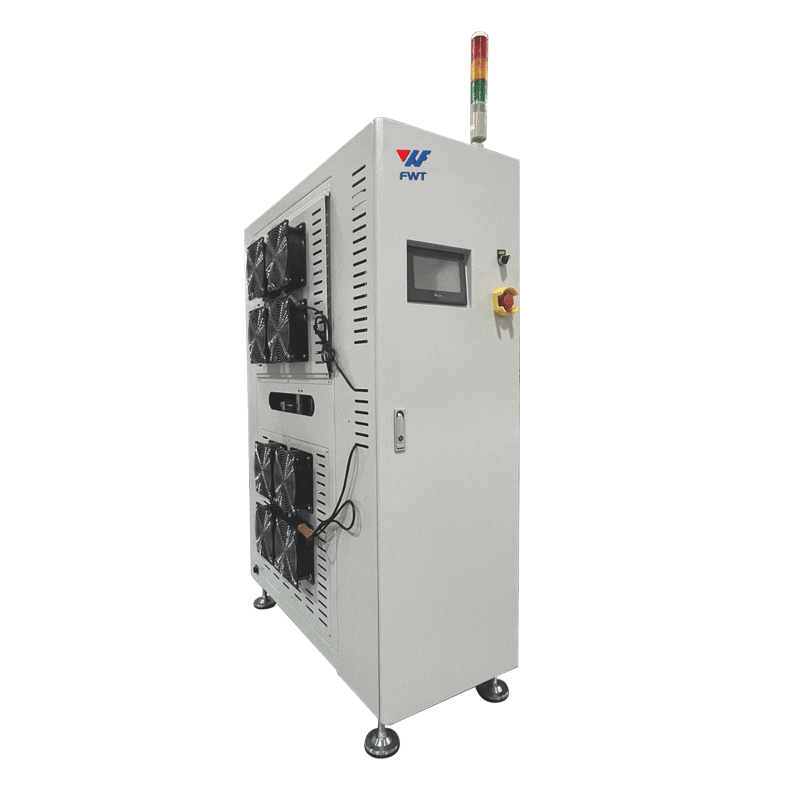

Product Parameters

|

Descriptive |

This equipment is used for two SMT production lines of PCB boards convergence of a reflow soldering or wave soldering over the furnace. |

|

Throttle |

500W |

|

Itinerary |

0.5-1.25M |

|

Meter |

7-15s |

|

PCB Width |

50-330mm |

|

PCB Thickness |

0.4-3.0mm |

|

Structural Options |

Single-vehicle single-action/double-vehicle single-action/double-vehicle double-action |

|

Product |

Magnitude |

Runners |

Models |

Overall Dimensions |

PCB Size |

Weight |

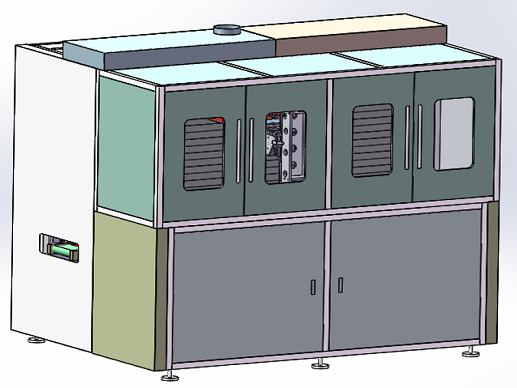

| SMT Parallel Shifter |

M DIP plug-in |

Bicycles |

FWT-250TC |

1750*500*1250mm |

50*50-450*350mm |

240kg |

|

L |

Bicycles |

FWT-400TC |

L(Customizable)*500*1250mm |

50*50-450*350mm |

270kg |

|

|

LL |

Tandem |

FWT-46TC2 |

L(Customizable)*500*1250mm |

50*50-450*350mm |

320kg |

Latest News

-

What are the exhaust treatment methods for vertical curing ovens?

Vertical curing oven exhaust treatment methods mainly includ...

-

Some suggestions for PCB baking

As we all know, PCB processing is completed, with a certain ...

-

How to place the PCB board in the oven is the most appropriate

Curing ovens produced by Forward have multiple electrical ci...

-

What are the benefits of a static vertical oven?

Suzhou Forward Machinery Manufacturing Co. produces static v...

Contact Us

24-hour Call0512-65201865 / 133-8217-7188

—— Add Microchannel