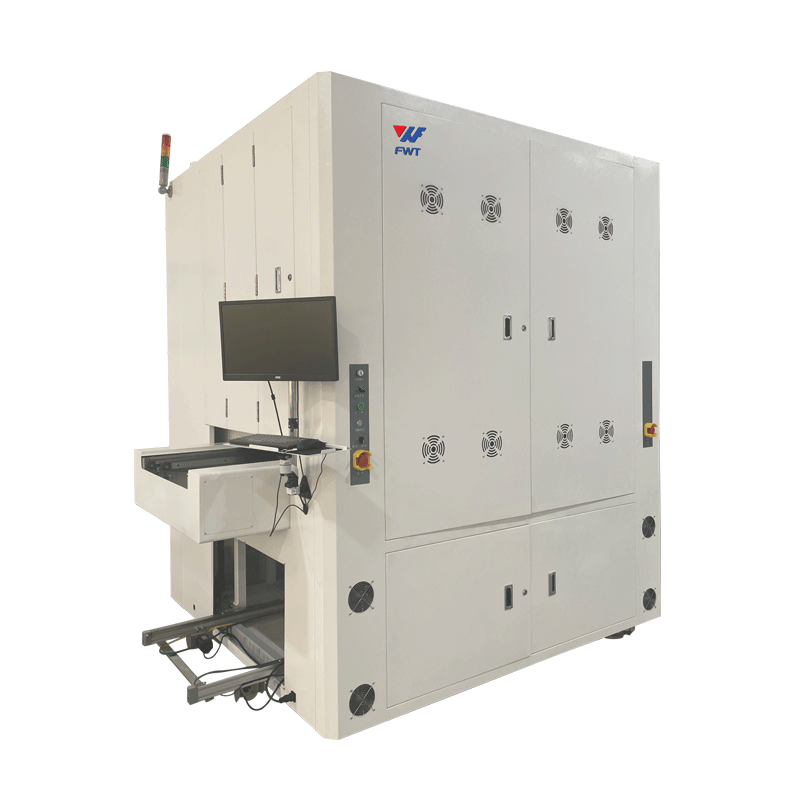

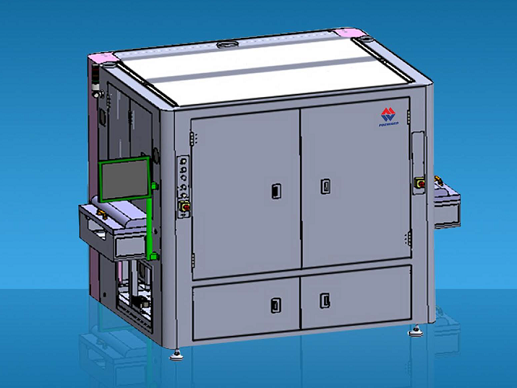

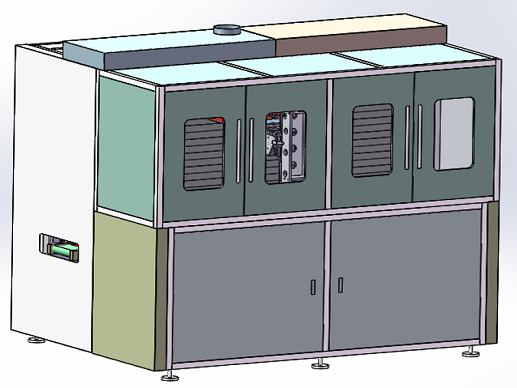

| Product Model | FWT-250 | FWT-330 |

| Feeding Method | Automatic connection to the production line | Automatic connection to the production line |

| Stocking Method | Vertical Storage | Vertical Storage |

| Number of stockpiles | 50-70 Work Pieces | 50-200 Work Pieces |

| Curing Time | 1~60min | 1~60min |

| Warming Time | 30min | 30min |

| Temperature control method | PID+SSR | PID+SSR |

| Temperature control range | Indoor Temperature~200℃ | Indoor Temperature~200℃ |

| Temperature Accuracy | ±2℃ | ±2℃ |

| PCB Size | 50~250(Selectable) | 100~350(Selectable) |

| Start-up/normal operating power | 16KW/4KW | 18KW/8KW |

| Control System | PLC+Microcomputer Control | PLC+Microcomputer Control |

| Abnormal Alarms | Tri-color signal light+Human-machine interface prompts | Tri-color signal light+Human-machine interface prompts |

| Air Supply | 6Mpa | 6Mpa |

| Power Supply | 380V/50Hz | 380V/50Hz |

| Body Size | 1900*1650*1800mm | 2100*1650*1900mm |

| Body Weight | 1800KG | 2000KG |

Note: Can be customized according to the actual needs of customers.

Latest News

-

What are the exhaust treatment methods for vertical curing ovens?

Vertical curing oven exhaust treatment methods mainly includ...

-

Some suggestions for PCB baking

As we all know, PCB processing is completed, with a certain ...

-

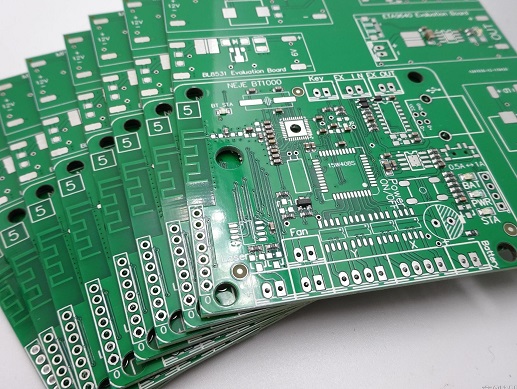

How to place the PCB board in the oven is the most appropriate

Curing ovens produced by Forward have multiple electrical ci...

-

What are the benefits of a static vertical oven?

Suzhou Forward Machinery Manufacturing Co. produces static v...

Contact Us

24-hour Call0512-65201865 / 133-8217-7188

—— Add Microchannel